Detail Post Floor Details First In Architecture

Cite: Franco, José Tomás. "21 Detailed Construction Sections for Wood Structures" [En Detalle: Cortes Constructivos / Estructuras de Madera] 04 Mar 2018. ArchDaily. (Trans. Gosselin, Marina.

Cross section of rigid core engineered hardwood showing the layers Engineered hardwood

The mass required for a timber floor is less than that of a concrete floor because the material is softer and radiates sound less efficiently. Diagram HE28 - Types of floors - Extract from TGD E. To ensure floor construction is fully effective, care should be taken to correctly detail the junctions between the separating floor and other.

Timber floor

Design information for TJI 110-560 joists. Designing the framing system for engineered lumber is a little different from dimensional lumber. While dimensional lumber, still the most common way to frame, is usually 1½ in. by 9¼ in. or 11¼ in. (or sometimes 7¼ in. or 5½ in.), engineered lumber comes in various widths, in depths of 9½ in.

How To Install Engineered Hardwood Floor Flooring Designs

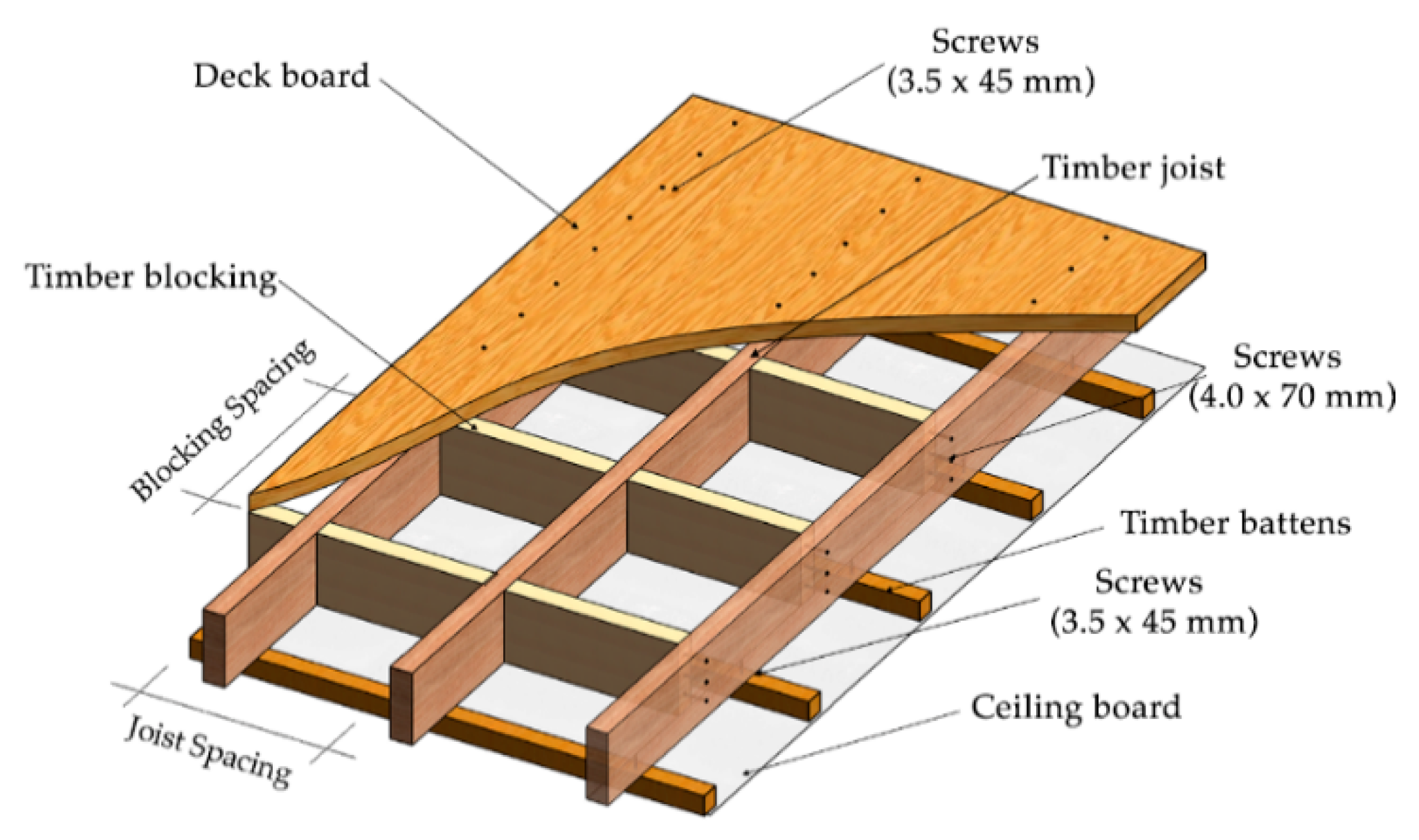

Timber floor construction consists of boarding supported by timber joists (bridging joists or floor joists) which are nailed to wall plates on their ends and supported by a sleeper or dwarf wall lengthways. The different types of timber joists. Timber joists are essential components in many construction projects, providing a framework to.

Building Guidelines Suspended Timber Floors

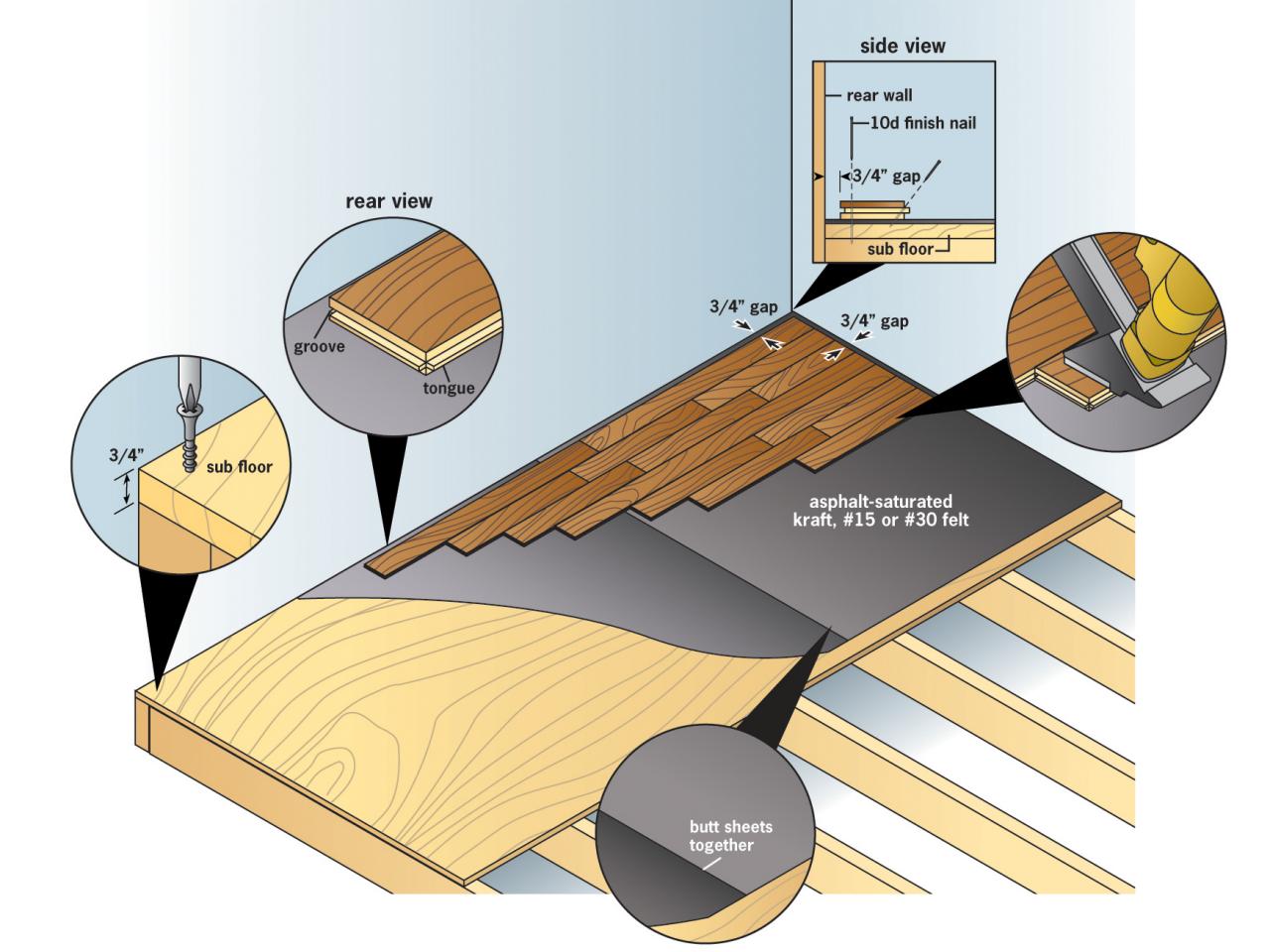

#09 • Timber Flooring Design Guide Page 4 Introduction Scope This publication provides a reference guide for the installation of solid timber strip flooring over bearers and joists, timber-based sheet flooring products and concrete slabs. Generally, floors of this type are of solid timber or a laminated product made from layers of timber,

How to Install Prefinished SolidHardwood Flooring howtos DIY

Timberlinx (877.900.3111) is a Canadian firm that offers a unique range of hidden timber fasteners that require nothing more than accurately drilled 1 1/8" holes. A special jig makes it easy to bore these holes square. The system works in traditional solid wood beams as well as modern glulam or microlam timbers.

timber floor detail floating Google Search Timber flooring, Acoustic insulation, Floating floor

Cross-lami nated timber, or CLT, is the rising star of the mass timber structural family, yet the BIM user is often faced with a lack of detailing and dimensional coordination information for a young industry segment that is not yet fully standardized across the different producers. We started this catalog library with mass timber floor assemblies (horizontal system families used like a slab.

FloorFraming Design Fine Homebuilding

The more pounds of force needed, the harder the wood. Example: balsa (a super soft wood) has a Janka rating of 70. That means it only takes 70 pounds of force to push a steel ball into it, making it a *horrible* flooring option. Maple, on the other hand, has a Janka rating of 1450.

Flooring Flooring, Home construction, Floor framing

Timber-Concrete Composite Floors. As part of its research work on wood buildings, FPInnovations has recently launched a Design Guide for Timber-Concrete Composite Floors in Canada. This technique, far from being new, could prove to be a cost-competitive solution for floors with longer-span since the mechanical properties of the two materials.

Timber Floor Technical Information Knauf Insulation

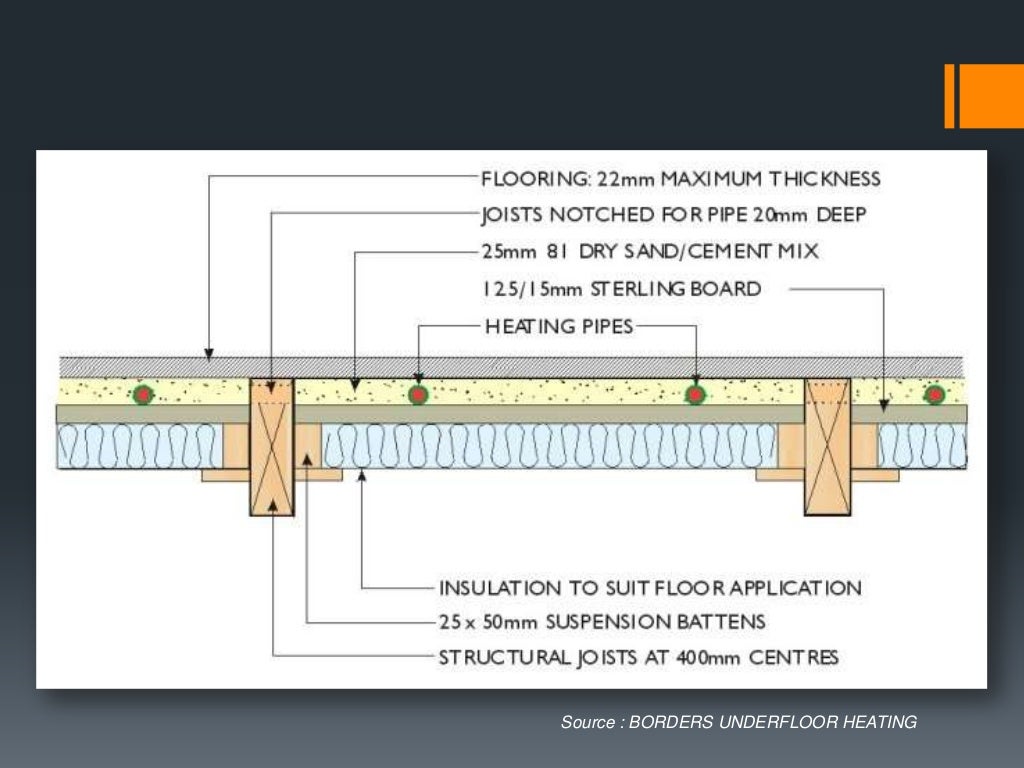

Floor Structure: Floating Floor type: Underfloor Heating Thickness Robust Detail Solid timber joist: Timber deck on resilient battens: No: 384mm E-FT-2: 423.5mm E-FT-8 Engineered I-joist: Timber deck on resilient battens: No: 403mm E-FT-1: 423.5mm E-FT-7: Wet screed: No: 451.6mm E-FT-4: Dry screed board: Yes: 346mm E-FT-5 Metal web joist.

Technical Details Book of Details Chapter 3 Timber frame construction, Timber architecture

Single joist timber floors 2 c Joist Span (below 3m) Strutting a b PLAN Detail at c' Air space Floor boards Joist Wall Wall plate Ceiling Section on ab Joist Wedges Floor boards 300 - 400 mm Herring bone strutting Double joist timber floors 3 1.8m to 2.4m 3.6 to 7.5m 300mm Binders Bridging joist @ 300 mm c/c PLAN Methods of fixing binders.

Building Guidelines Suspended Timber Floors

Diagram B47 - Typical detail of timber floor suspended by tassel walls. If the fill depth is greater than 900mm, joists should span from perimeter to perimeter, if required an intermediate support can be provided (i.e. a steel beam). If steel is to be used to reduce the span, steel must be designed by an engineer.

How To Install Hardwood Floors Over Concrete Slab Flooring Ideas in 2020 Diy wood floors

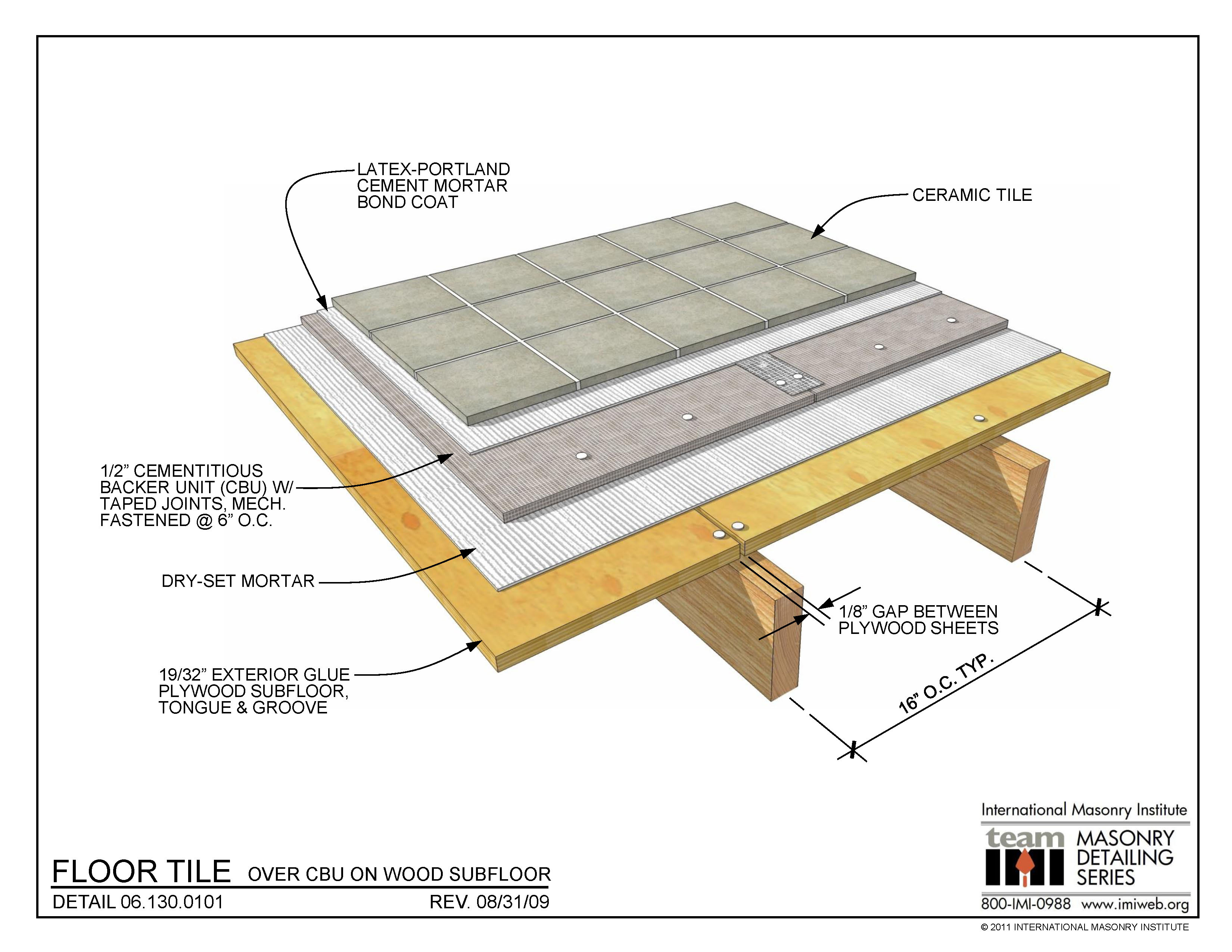

Introduction to Floor Details. The most common materials used for the construction of ground and upper floors tend to be concrete or timber. Required span, resistance to passage of sound, and fire resistance will often be factors to consider when deciding which material to use in floor design. The Building Regulations in the UK provide guidance.

06.130.0101 Floor Tile Over CBU on Wood Subfloor International Masonry Institute

A floor's framework is made up mostly of wooden joists that run parallel to one another at regular intervals. Floor joists are typically 2 by 8s, 2 by 10s, or 2 by 12s; ceiling joists are usually 2 by 6s or sometimes 2 by 4s if it is an older home. Some newer homes have manufactured, I beam-shaped joists. Floor joists, spaced on regular.

Flooring Home construction, Floor framing, Building a house

Fig-3: Isometric View of Double Joist Timber Flooring Fig-4: Plan for Double Joist Timber Floor Fig-5: Section X-X Framed or Triple Joist Timber Floor. This type of timber flooring is suitable for spans between 5 to 7.50 m and the superimposed load is very heavy. The intermediate supports known as girders are provided for the binders.

Timber Timber Massivholzbett Bei Hoffner Mobel Hoffner Wood, especially when suitable for

Modified — timber physically modified in a process that changes its properties to enhance its durability to an appropriate level. Larch is a great example of a naturally durable commonly used softwood in cladding. It weathers to a lovely grey and can be purchased pressure treated, helping to further extend its lifespan to a minimum of 10 years.